Ruck Air Movement S-Prime Evo Mixed Flow Fan, 6" - 400 CFM

Sign in to create a new quote.

Description

Sound insulated casing for silent operation

S-Prime & S-Prime Evo Fans offer off great efficiency rates with the added benefit of sound insulation. Manufactured in Germany, S-Prime fans are built with powerful motors, strong galvanized steel housings, and a mixed-flow impeller design. Steplessly controllable, one-phase AC motors produce reliable airflow rates while cutting energy costs with reduced power consumption.

Available in the following sizes:

- 6"

- 8"

- 10"

- 12"

Features & Benefits of Ruck Prime Mixed Flow Fans

Diaganol fan with three-dimensionally curved impellar blades and robust housing made of galvanized sheet steel, plastic, or aluminum as well as...

- Sound insulated casing for silent operation

- Incorporated Prime Evo mixed flow fan

- Very high efficiency rates

- Integrated 3-speed switch - (all models except 12")

- One-phase AC motor

- Galvanized sheet steel casing

Determining your requirement - Exhaust vs Recirculating (Scrubbing)

You will need to determine whether or not you are exhausting (going from a contaminated environment to a sterile environment in only a single pass through the filter) or recirculating, aka “scrubbing” (exhausting the system back into the contaminated space).

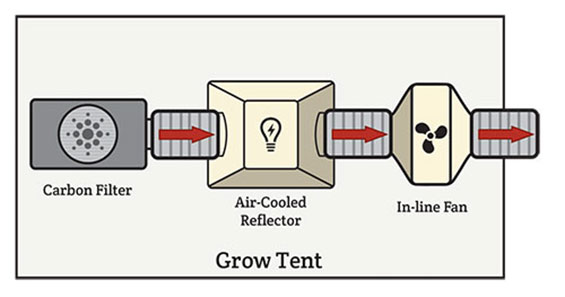

Exhaust

In an exhaust setting the air only passes through the filter one time so it is imperative that we remove as close to 100% of the contaminate as possible with that one chance. This requires that the contaminant have a certain time in contact with the carbon in order to be fully adsorbed. Our filters are marked with both exhaust and recirculating ratings for just this reason. If you are using this system to exhaust, DO NOT exceed the exhaust rating for the filter, the more this rating is exceeded the less contaminant will be adsorbed because the two will not have enough contact timefor adsorption to fully take place.

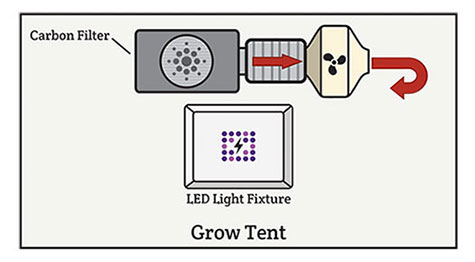

Recirculating

In a recirculating system , the contact time is not such a crucial number as we are taking contaminated air, filtering it, and releasing it back into what is typically and constantly decontaminated environment. It is for this reason that it is not necessary to remove 100% of the contaminant in a single pass. Instead we double the exhaust rating which will reduce the contact time, the goal here is to still remove a large portion of the contaminant but to get raise the cycle rate of air through the filter above the rate of emission from the source. Now, instead of removing 99.9% of the contaminant in a single pass we are getting closer to 60% but we are getting twice as many cycles through the filter in the same amount of time and over time, reducing the overall build-up of contaminant in the environment.

Sizing Your Space

Once you’ve determined the type of system you need, it’s time to size your space.

Typically for exhaust we recommend a simple length x width x height /3 calculation. This will give you the amount of air (cubic feet per minute, CFM) that you will need to move to properly ventilate your space allowing for a three-minute air exchange (all the air in the space is exchanged for fresh air every three minutes). This is the number you will match your filter to.

Example:

Room size: 10’x12’x8’ (960 cubic feet)

960 cubic feet / 3 minutes = 320CFM (Minimum recommended CFM to exchange the air every 3 minutes)

For recirculating systems, you can use the same length x width x height but divide by 1.5. This will give you a high cycle rate while still ensuring the removal of a majority of contaminant with each pass through the filter.

Specifications:

| VT-IFRSPE-6 | VT-IFRSPE-8 |

|---|---|

| CFM: 400 | CFM: 784 |

| RPM: 3298 | RPM: 3192 |

| 120V / 0.6A / 68W | 120V / 1.5A / 179W |

| VT-IFRSP-10 | VT-IFRSP-12 |

|---|---|

| CFM: 1035 | CFM: 1692 |

| RPM: 3001 | RPM: 3407 |

| 120V / 1.9A / 221W | 120V / 4.2A / 479W |