Faven Lighting R8 46 Inch 120 Watt Under-Canopy LED Grow Light Bar, 120-277 Volt

Sign in to create a new quote.

Description

Boost Your Yield & Crop Health with Faven Under-Canopy Lights!

These are lights designed to sit beneath plant canopies where top lights can’t quite reach. Faven’s under canopy lights are the best way to improve the yield and health of your plants with minimal increase to operational costs. Made to supplement overhead light installations, this under-canopy light offers a low-maintenance way to:

Features & Benefits of Faven Under-Canopy Lights

- Increase flowering

- Give your plants more consistent growth and color

- Increase concentration of potency and some terpene compounds

- Decreases labor costs by eliminating the need for under-clearing "lollipopping"

- Compatible with Trolmaster and Vivosun dimming controllers

- Can daisy chain up to 20 lights together

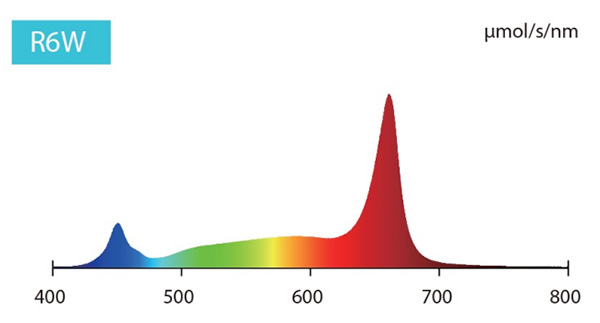

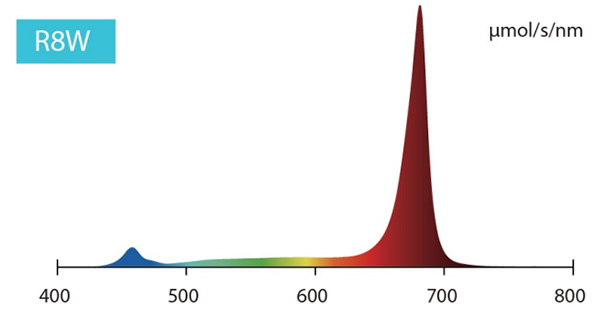

- Come in either 60% red spectrum or 80% red spectrum

Choose Your Spectrum

Faven offers two different spectrums based on the type of top lighting being used inside grow rooms or greenhouses - this is called "Spectrum Balancing." The goal is to supplement additional spectrums and wavelengths that may be lacking in current lighting layouts. This gives cultivators greater control over the quality of the product being produced. While adding Favens to your facility will increase yield, increasing the product quality is also a top priority.

R6 lights (60% red) compliment HID top lights that are high in ROY

R8 lights (80% red) compliment full spectrum LED top lights.

Consistent Light Spread

The lenses on both types have a bubbled shape to diffuse light evenly and increase canopy penetration.

Dimming Capabilities

These lights are compatible with dimming controllers so you will have complete control over light intensity throughout the growth process. Flaven lights can dim down to 35 - 40% if their maximum intensity.

Waterproof and Able to Connect

Waterproof connectors with an IP66 rating allow you to connect up to 20 lights with extension cords (sold separately) for a large layout that will be perfectly safe with any irrigation system.

Hear What Professional Growers & Top Tier Growing Companies Have To Say

The following testimonials and comments we received directly from growers using Faven Under Canopy Lighting. Real growers, real facilities, using Faven Under-Canopy lighting to achieve better yields, and higher quality flowers, all while raising the standards in the industry.

Bill (Chocolate) @Hytek Detroit

"Faven is revolutionizing indoor growing. Our whole outlook on lighting has changed."

"From the initial consultation to delivery, Faven has backed up their lights with a great product and support."

Mo @AJS Flowers

"It was easy to install and maintain. We saw an immediate 20% increase in yield and more color throughout the entire plant. I recommend it to any grower trying to increase yield and quality!"

Zach Goodin @Amplifed Farms

“We saw a 43% increase on a specific strain. About 28% average on the other genetics in rotation. You could say Faven’s work really well.”

Mike Strupp @WoodWideFarms

"Faven lights were the best thing we added to our grow rooms in years. The ROI happened in the first round, and our yields were up, as was the quality."

@TheCureCompany

"Faven works great. Yes, my yield went up at least 20 percent, and color dropped all the way through the canopy 4.3lb for 22.5 sq ft of canopy."

Ryan @WoodWideFarms

"Faven Under Canopy lights are the best thing to happen to indoor cultivation in the past decade."

Why hold yourself back from growing the best you can? Be the best grower you can, and start growing top-shelf product with Faven Lighting.

How many lights do I need?

Convert your bench length to inches, then divide by 46". That is how many lights each row can support. These lights are a modular system giving you the flexibility to set these up in whichever configuration works best for you! Not seeing a configuration that fits your grow? Give us a call today at 888-815-9763 and one of our experts will help you get what you need!

Example: 14' bench length, 3 plants wide

14' x 12" = 168", 168" ÷ 46" = 3 lights (round down)

3 x 2 (available rows in-between plants) = 6 lights

How many power cords and extensions do I need?

Each bench requires at least one power cord. Depending on your total lights, you can daisy chain your rows with an extension. If you exceed max daisy-chain #, you will need two or more power cords per bench.

Faven Under-Canopy Lighting Layout Examples

Scenario 1

240 volt, 4 lights per row, 1 rows of lights, 1 lights total = One 240v power cord per bench

Scenario 2

240 volt, 6 lights per row, 2 rows of lights, 12 total = One 240 v power cord and one extension cord per bench

Scenario 3

240 volt, 12 lights per row, 2 rows of lights, 24 total = Two 240 v power cords per bench

Scenario 4

240 volt, 8 lights per row, 3 rows of lights, 24 total = Two 240v power cords and one extension per bench

NOTE: 4' Wide Bench recommendations

If the facility bench width is 4' or less and you are running four plants wide, we recommend dropping the plant count to three plants wide. We've seen great results in reducing plant count in our trials. A lower planting density promotes greater air flow which drives production in the lower canopy.

Optional Upgrade: TrolMaster Hydro-X Controllers

The Hydro-X series is a professional-grade and modular designed environmental control system, that supports most of the control modules and sensors within a single growing zone, and also allows flexible customization and further expansion.

There are 3 different Hydro-X models: Hydro-X / Hydro-X Plus / Hydro-X Pro, to satisfy the needs of different types of growers. All the Hydro-X systems can control most of the horticultural lighting systems like Faven Lighting using LMA-14. 2 separate built-in lighting control channels offer controllability on 2 different lighting systems at the same time. The PPFD level could be automatically adjusted followed by the PPFD PAR meter.

Hydro-X

Hydro-X Plus

Hydro-X Pro

The Hydro-X Environmental controller from TrolMaster is one of the most sophisticated light controllers on the market. By combining this controller with your Faven Under-Canopy LED, you bring in an entire suite of professional tools to to maximize your light and yields.

A single LMA-T Adapter is all that is needed with the controller and you are ready to start controlling your Faven LEDs with TrolMaster

How Under-Canopy Lights Change Cultivation Workflow

Under-Clearing

Perhaps the biggest change to a typical cultivation workflow will be the reduction of under-clearing, also known as "Skirtting" or "Lollipopping". By leaving lower branches and bud sites intact, you will be able to increase your usable canopy depth by 2ft to 3ft. Small branches and bud sites that sit below the light source can be removed. Faven recommends leaving as much foliage on the plant untouched until "Strech" or "Stack" is complete. This will allow the grower to accurately see what will turn into usable products and what can be removed. This process is best done between days 22-26 of the flower phase.

Deleafing

Deleafing for light penetration is not a new concept. However, the Under-Canopy application adds another factor to think about when removing leaves. The overall goal is to remove just enough leaves to create a mix of light in the middle of the canopy from both the top and bottom light fixtures. This approach blends the two main schools of thought widely practiced in cultivation: The dead strip (no fan leaves) and leaving as many leaves as possible. While removing too many leaves can be detrimental to the photosynthetic ability of the plant, not taking enough leaves blocks light from reaching bud sites located in the middle canopy. It's a balance that will likely take a run or two fully dialed in and standardized.

Planting Density

The third difference that is often overlooked when adding under-canopy to your cultivation is planting density. While density greatly varies across the industry, a constant that has been observed is the benefit of reducing plant count when adding under canopy lighting. The decrease will be different for every facility. Lowering plant count promotes more airflow and keeps bottom branches from blocking under-canopy lights. Instead of removing leaves to improve airflow and upward mobility of under-canopy light, reducing plants achieves the same result. Fewer plants also mean a reduction in labor from the nursery through post-production. Reducing plant count can be a scary thought, so we recommend starting with a single trial table and comparing results. In almost all cases, lower plant density outweighed control tables.

Specifications for the Faven Under-Canopy Lighting

Faven LED light bars can be electrically connected end-to-end or with extension "jumper" cables. See the installation manual for detailed instructions.

| Voltage | Max # of connected | Current |

|---|---|---|

| 120 | 10 | 1.0A |

| 240 | 17 | 0.50A |

| 277 | 20 | 0.43A |

| Input Power | 120 Watts |

|---|---|

| PPE | Up to 2.9 µmol/J |

| PPF | Up to 340 µmol/s |

| Input Voltage | 120V, 240V, 277V |

| Input Current | 1.0A, 0.5A, 0.43A |

| Thermal Management | Passive |

| Operation Temperature | 95° Max |

| Dimming | 25-100%/Off |

| Daisy-Chain | Up to 20 lights |

|---|---|

| Lifetime | >50,000 Hours |

| Safety Certification | ETL, DLC, CE, FCC, IP66 |

| Light Distribution | 120° |

| Warranty | 5 years |

| Frequency | 50/60 Hz |

| Dimensions | 45.6" x 2.9" x 3.3" |

| Weight | 5.73 lbs. |