Description

The CenturionPro GC Bucking Machine Combines Power and Efficiency

The brand new CenturionPro GC Bucker is an operator-run de-stemming machine that requires the operator to apply gentle pressure to feed the stem in the machine. GC refers to ???Gentle Cut??? as we appreciate and understand how delicate your flowers are. Similar to scissors, this Bucker cuts the flowers off the stem, as opposed to pulling and popping them.

This cutting action prevents the large crown buds from breaking apart into smaller pieces, thereby keeping the complete structure of the buds fully intact preserving the look of your flower.

The single GC bucker accepts stems up to 3/8" in diameter and can do the work of 2-3 human workers and will buck 40+ pounds per hour of fully hydrated flowers (8lbs dry flower)! The GC1 features a continuous duty cycle and active gearing drivetrain which allows even more control and exceptional efficiency ??? while still keeping safety in mind.

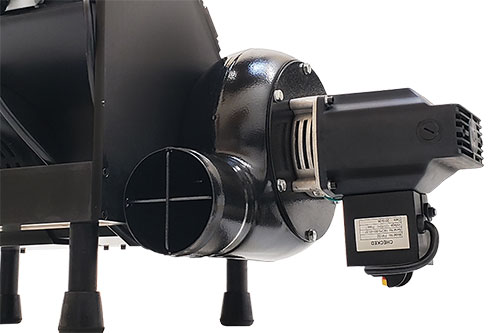

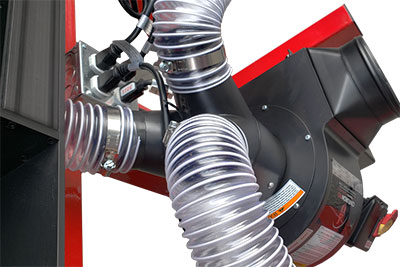

The GC bucker also comes with a cleaning system which removes and collects all debris into a vacuum bag, making clean up a breeze. The system is easy to set up, clean, requires little maintenance and comes with a 5 year warranty.

Key Features:

- Feed Throughput: GC1 +40 lbs/hr, GC3 120 lbs/hr

- Feed Entry Sizes: 3-hole (3/16", 1/4", 3/8")

- Primary Material: 304 Stainless Steel / Aluminum

- Feed Types: Wet/Dry

- GMP/UL/CE/RoHS Comliant

GC1 Bucker with Stand & GC3 Bucker with Stand

You can upgrade your GC1 bucker to include a bucker stand. Make the most of your processing time with the added ease of de-stemming and improve portability as our bucker stands to operate on a 4-wheel system. The bucker stand comes standard with industrial casters. Choose to purchase an Off-Road Wheel Assembly Kit upgrade

The GC3 Triple Bucker comes with the stand already included for added value. The bucker stand comes standard with industrial casters. Choose to purchase an Off-Road Wheel Assembly Kit upgrade.

Keeping with CenturionPro??™s reputation for innovation, the GC3 Triple Bucker is pushing the boundaries as the first-ever three-station bucker on the market!!! Whether you buck wet or dry, the GC3 Triple Bucker will successfully de-stem your flower at a rate of 120+ pounds per hour of fully hydrated flowers (24lbs dry).

In aligning with our goal of being as gentle as we can on your flower, this system also provides unparalleled processing capacity. The three workstations and multiple holes for various stem size pairs well with CenturionPro??™s industrial trimming machines such as the Gladiator and 3.0. The GC3 Triple Bucker comes complete with three 0.25 HP gear-driven motors to provide unsurpassed power.

In addition, this triple workstation features a cleaning system, which removes and collects all debris into a vacuum bag, making clean up a breeze.

The system is easy to set up, clean, requires little maintenance and comes with a 5-year warranty.

Preparation for using the GC Buckers & Tip for Dry Bucking

Environment Preparation

- Ensure adequate space

- Review electrical requirements

- Have adequate bins for product transport

- Cooler temperatures in processing room is beneficial

Plant Preparation

- Cut main stalk

- Seperate each individual stem (no 'y' junctions)

- Leave 3" of stem for clearance into machine

- Ensure clean angled cuts for precise feeding

Feeding

- Keep prepped product stem side up for efficiency

- Size the stem to fi t the ideal hole

- Feed end first into machine

- Use variable speed control to adjust flow

Moisture Content

- Moisture content is critical for ensuring minimal damage to the flower

- Flower that is too dry will fall apart

- Flower that has too much moisture will compact and dent

- For best results with dry bucking, moisture content should be between 12% and 14% when using a machine

Bud Consistency

- Buds should be "springy"- when the flower is squeezed between two fingers it will rebound and return to its original shape

- Both big and smaller stems must be pliable when bucking with a machine such as a GC or HP System

- Pliable stems ensures that they fold and are stripped upon entering the bucking machine. If too brittle, they will simply break off and will not be properly stripped

Machine Speed

- Slowing the machine speed for dry bucking will lead to a better result

- Dry bucking at 1/2 or 1/3 of the regular speed will ensure better results

- The variable speed control off ered by our HP Bucker is a great feature when bucking dry material

Specification for the GC1 & GC3 Bucking Machines

| Model | GC1 |

|---|---|

| Input Voltage | NA: 6 Amp - 110V, 60Hz Single Phase EU, AUS: 3 Amp - 220V, 50Hz Single Phase |

| Current Draw | < 3A Operating |

| Motor | 0.25HP |

| Motor RPM | 1750 RPM |

| Weight (w/o stand) | 40lbs /18kg |

| Length | 28in / 71cm |

| Width | 14in / 36cm |

| Height | 15in / 38cm |

| Circuit Creaker Required | NA: 15A/120V EU, AUS: 15A/220V |

| Model | GC3 |

|---|---|

| Input Voltage | 25 Amp - 110V, 60Hz Single Phase EU, AUS: 9 Amp - 220V, 50Hz Single Phase |

| Current Draw | < 23A Operating |

| Motor | 0.25HP (x3) |

| Motor RPM | 1750 RPM (x3) |

| Weight (w/ stand) | 520lbs /236kg |

| Length | 85in / 216cm |

| Width | 32in / 82cm |

| Height | 51in / 130cm |

| Circuit Creaker Required | NA: 30A/120V EU, AUS: 20A/220V |